Profile

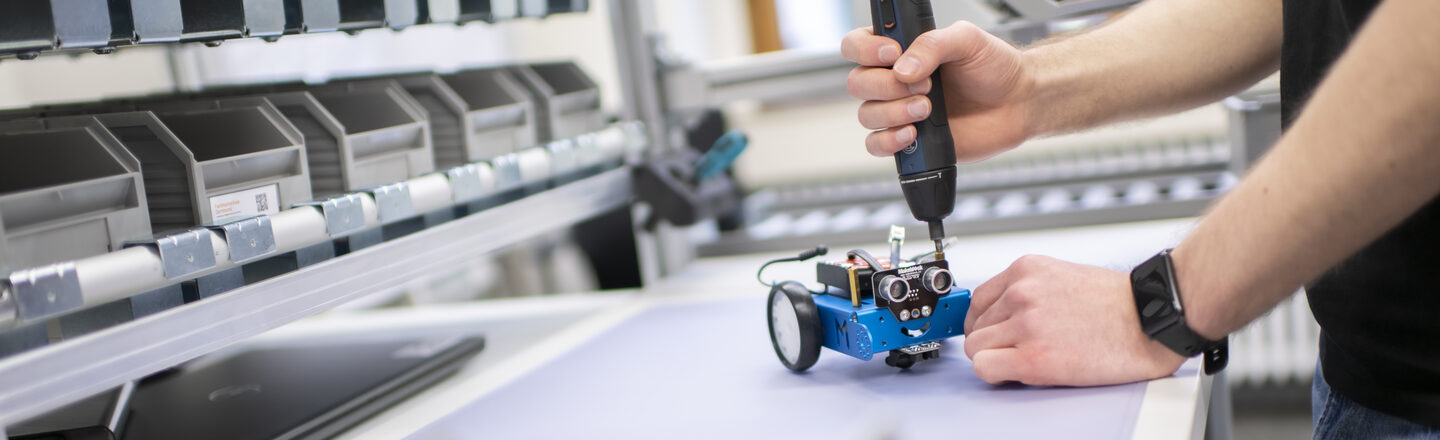

The Lean Lab demonstrates various possible applications of configurable manual assembly systems for a selected small-volume product. In addition to various material flow linking options, the information flow is also illustrated on the basis of an ERP system. In addition, the potential of digitalization in manual assembly is demonstrated with the help of assistance and collaboration systems. The practical implementation of the lean manufacturing concept and digitalization, the successes that can be achieved and how this can be integrated into a company's production organization cannot be fully conveyed on a purely theoretical level. Therefore, the core idea of the facility is to test lean concepts and Industry 4.0 technologies in practice and make them tangible for students and cooperating companies.

Equipment

- Digital assembly planning

- Digital value stream mapping & design

- Digital store floor management

- E-Kanban system

- Enterprise Resource Planning (ERP) System

- Ergonomic workstation

- Collaborating robot

- Manufacturing Execution System(MES)

- Pick-to-Light System

- Production simulation

- Virtual reality headset

- Worker assistance systems

Service & Offer

For students

The Lean Lab can also be used for students' final theses and project work. Students can work on practical tasks by examining the topic from a scientific perspective and then putting their developed concept into practice in the laboratory.

For companies

What do we offer?

- Workshops to impart theoretical and practical knowledge on the design of production systems and workplaces as well as the methodology of lean management. This includes 5S, one-piece flow, ergonomics, store floor management, standardization, value stream management, zero-defect principle, digitalization and much more

- Practical implementation of the lean management methodology in our lean lab as a learning, simulation and test environment for companies

- Counselling for companies that want to reorganize or optimize their production system in line with lean management thinking

- Support with the digitalization of production processes and the introduction of Industry 4.0 technologies

- Research and development cooperation with companies as well as application for and implementation of funded research and development projects

- Marketing for our cooperation partners: students and companies get to know your product and your company in a realistic application environment in the Lean Lab

- Quarterly working group meetings for an in-depth professional exchange between industry and science on various topics relating to lean management and digitalization

What are we looking for?

We are looking for companies that are interested in a long-term cooperation with the Lean Lab at Fachhochschule Dortmund:

- Companies as exhibitors: Their products and technologies (also as prototypes) are used in the Lean Lab and optimized in close cooperation if necessary

- Workshops and training courses: We would be happy to plan an appointment with you for a workshop or training course for your employees that is individually tailored to the needs of your company

- Research and development: Together we develop innovative solutions for designing the production system of the future (as part of a funded research project)

Are you interested in working with us or would you like to book a workshop for your employees? Then please contact us at the e-mail address below and we will advise you on the individual implementation options for your company.

Cooperation partner

Projects

Contact

E-Mail:

lean.laborfh-dortmundde

Contact persons

Leonie Potthoff, M.Sc.

By appointment - available by e-mail or via MS Teams

Rolf Naussedat, B.Eng.

By arrangement

Preferably to be reached via Teams