Profile

The Vehicle Drives Laboratory at Dortmund University of Applied Sciences is working on pioneering ideas in the field of vehicle drives. In the field of piston combustion engines, seven (partly fully dynamic) test benches with up to 700 kW braking power are available in the very well-equipped laboratory for vehicle drives. Research focuses on the analysis and synthesis of energy-saving and low-CO2/free system concepts.

The team at the Vehicle Drives Laboratory is breaking new ground here in order to achieve the goal of CO2-neutral energy use and a reduction in the required drive power. Research areas are cylinder pressure-based combustion control, alternative fuels and variability of valve and crank drive on combustion engines (especially for commercial vehicles and industrial engines).

In addition to the development of vehicle drives, the development of measurement and automation technology as well as designs in the field of drive technology are further focal points.

Unfortunately, the video "Laboratory for vehicle technology" provided here cannot be displayed.

Hydrogen for vehicle drives

The Laboratory for Vehicle Drives at Fachhochschule Dortmund is currently setting up facilities for testing fuel cells, electrolyzers and hydrogen combustion engines. This includes the integration of an electrochemical impedance spectrometer for detailed analysis of cell performance and degradation as well as extensive safety technology for handling and storing hydrogen. In future, extensive advanced measurement technology and safety equipment will be available to ensure safe operation. Several projects are already underway in the areas of fuel cells and hydrogen combustion engines.

LaSiSe

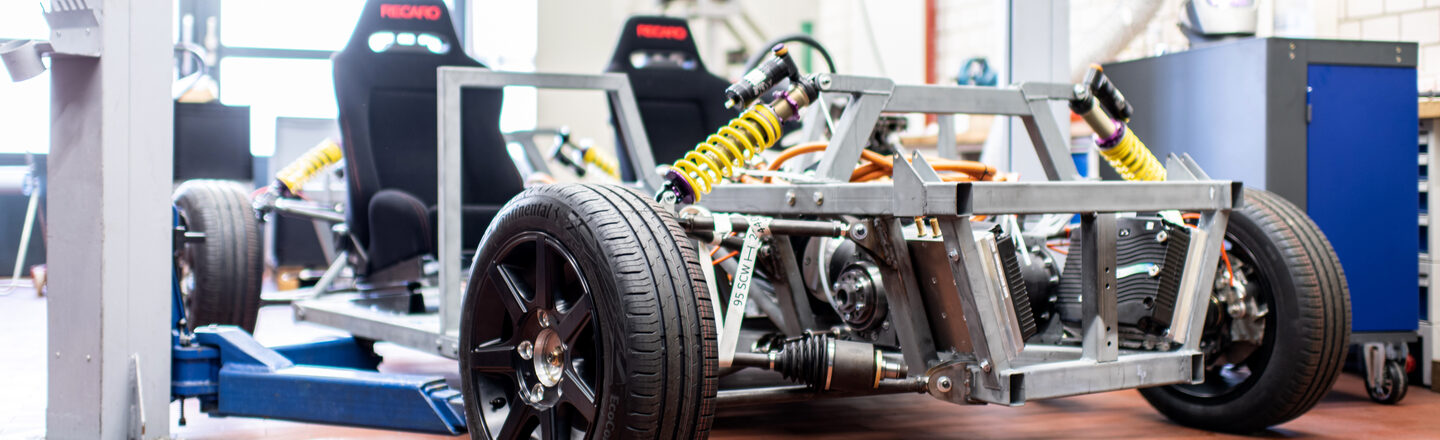

The use of the test track was made possible by a cooperation agreement concluded in 2017 between the FH and the Research and Technology Center for Load Securing Selm gGmbH (LaSiSe).

Since then, many technologies in the field of chassis, vehicle drives and also the entire vehicle can be examined together with students on the test track.

In addition to laboratories for electronic and precision mechanical work, a complete workshop equipment with lifting platform is also available for teaching and research.

Equipment

Main areas of activity

- 3 test benches for stationary engines

- 2 dynamic test benches for off-road and non-road engines

- Engine intensification possible on request

Euro 4, 5, 6 for off-road engines

Stage III A,B/ IV/ V for non-road engines - Exhaust gas aftertreatment

- Engine applications

- Marine applications

- Engine endurance tests

Test field equipment

- Development test benches for combustion engines

- Stationary and dynamic load machines

- Automation and measurement data acquisition systems

- Exhaust gas measurement technology

- Flow measurement technology

- Temperature measurement technology

- Pressure measurement technology

- Measurement technology for rapid cylinder pressure indexing (TDC sensor)

Load machines

- Stationary development test benches for combustion engines up to 700 kW

- Highly dynamic test benches with 375 kW & 500 kW

- Training test bench diesel engine

| Exhaust gas measurement technology | Determination of | |

| Measurement of gaseous exhaust gas components |

Flame ionization detector (FID) |

THC, CH4 |

| Chemiluminescence detector (CLD) |

NO, NOx | |

| Paramagnetic analyzer (PMD) |

O2 | |

| Non-dispersive infrared analyzer (NDIR) |

CO, CO2 | |

| LaserGas II Monitor |

NH3 |

|

| Particle measurement technology |

Microtrol 6 |

Gravimetric particle measurement methods |

| Opacimeter |

Optical exhaust opacity measurement | |

| Smoke meter |

Optical soot measurement |

|

| Pegasor |

Particle mass and number |

|

| Cambustion |

Particle size, mass and number |

|

| TSI model 3790 |

Number of particles |

Service & Offer

- Services in the field of hybrid, petrol and diesel engines, including exhaust gas aftertreatment

- Training and consulting services in the field of CO2 balancing, hybrid drives, combustion engines and vehicle drives

- Endurance tests, certifications, testing of engine components

- Exhaust gas measurements and exhaust system optimizations, performance measurements, engine calibrations and validation of test equipment

- Development work and provision of (partly dynamic and largely fully automated) development test benches for combustion engines (passenger cars to commercial vehicles) with extensive measurement technology (indexing, exhaust gas measurement, pressure, temperature and mass flow determination, etc.)

- Development of test bench measurement and automation technology

- Special design in the field of drive technology

Contact

Contact person and management

Prof. Yves Rosefort, Dr.

- +49 231 91129280

Appointments by telephone arrangement